Material

ORANGE PEEL LEATHER

Study

Orange Peel Leather

Developing a biodegradable textile from orange peel waste.

Project Overview: This was a team project completed during my exchange at Delft University of Technology (TU Delft). The main focus of this project was the implementation of the Material Driven Design (MDD) method. In this approach, materials are understood as both experiential and technical, with the material itself serving as the starting point for creating meaningful design applications. The method is based on key premises, including the idea that a significant part of a user’s experience with a product stems from its physical materiality, and that designing with a material requires an in-depth understanding of its properties through hands-on experimentation and tinkering.

The Material Driven Design method challenges the traditional practice of selecting materials at the final stage of the design process. Instead, it positions the material as the central driver throughout all phases of design, leading to more holistic sustainability outcomes, meaningful user experiences, and functional advantages. Using this approach, my team chose to develop a natural composite with leather-like properties using natural ingredients, primarily derived from orange peel waste.

Elective Project: Material Driven Design

Duration: 10 Weeks

Group: Isabel Clement, Xinyi Chen, Alex Hirst, Fauve Hoofjes and Nuala Zwart

2025

Skills: SolidWorks Finite Element Analysis, Tensile Testing, Sewing, Photography, Indesign, Procreate.

Motivation

Our group was inspired to choose orange peels because we recognised them as a waste stream with significant untapped potential. We were drawn to their vibrant colour which could inspire our design. In addition, we were intrigued by the peels’ tough and protective nature which cares for the fruit during growth. We thought that this durability could contribute to our materials mechanical strength properties. These immediate observations had led us to explore their further value, which we recognise as their sustainability through reducing food waste, poor agricultural practices, and fast fashion.

Food Waste

Every year, approximately thirty-two million tons of orange peel waste is generated (MichaelIgolima et al., 2023). After becoming waste, orange peels take about six months to fully biodegrade, however the timeframe can vary depending on the environmental conditions they are exposed to. They decompose much slower than other organic waste such as vegetable scraps or coffee grounds. Furthermore, even after decomposition, orange peels may not always benefit the environment due to the potential presence of pesticides and chemicals used in their cultivation (Green, 2024).

Poor Agriculture Practice

Agricultural production is responsible for 80% of deforestation, with livestock farming being a primary driver (WWF, 2024). While the hide industry is not as demanding as the beef industry, leather production still exerts a significant environmental impact (WWF, 2024). In addition, in terms of animal welfare, standard practices in the slaughter of farm animals can often be violent and inhumane (Animal Welfare Matters To Leather Manufacturers, 2020). While some countries have more rigid guidelines enforced for the welfare of animals, on the consumer end it can be very difficult to trace where leather products are coming from, as well as assessing the transparency of the businesses involved (Animal Welfare Matters To Leather Manufacturers, 2020).

Fast Fashion

The fashion industry creates a large environmental impact contributing 8-10% of global carbon emissions. It is imperative that new practices are developed both in manufacturing and consumer behaviour. The fashion industry is particularly innovative and demonstrates experimental thinking within material and design, which is why we believe our material could be applicable and beneficial to this industry.

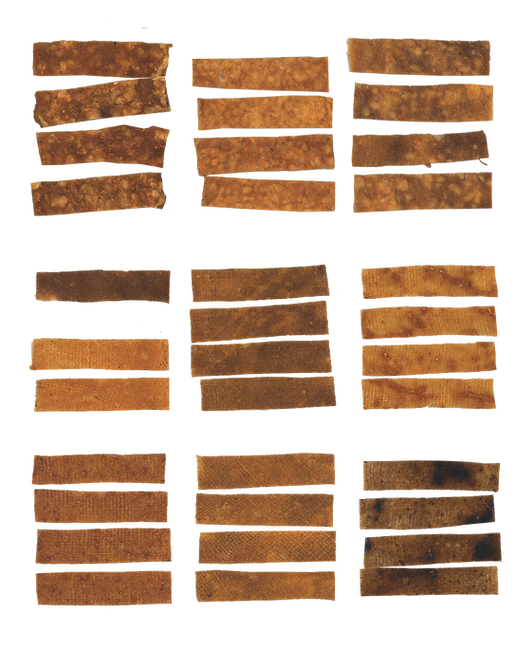

100% air-dried, wool fibre

Air-dried, with calcium chloride, wool fibre

Oven-dried for 3 hrs, wool fibre

Oven 30 mins + the rest air-dried, bilateral banana fibres, stored in the fridge

Oven for 30 mins + the rest airdried, no fibre

Oven for 1 hr + the rest air-dried, bilateral banana fibres

Oven-dried 3 hrs, bilateral banana fibres

100% air-dried, with calcium chloride, bilateral banana fibres

Air-dried for 1 day, oven 30 mins (reversed process), bilateral banana fibres

Oven 1 hr + the rest air-dried, quasilateral banana fibres

Criteria

We established four criteria for our orange peel leather. The two experiential criteria were a pleasant scent and a familiar, fabric-like feel. The two technical criteria were flexibility and strength. Together, these benchmarks guided our material testing and helped ensure we were progressing in the right direction.

Development

Numerous samples were produced through an iterative process of experimentation. We explored a range of ingredients and varying proportions, which deepened our understanding of how each component influenced the material’s feel, appearance, and strength. A key insight was the role of different fibre types and their impact on the final material. One of the primary challenges was reducing manufacturing time, with drying identified as the main bottleneck. We tested methods such as applying pressure and heat to accelerate drying, and ultimately found that a combination of oven drying and air drying yielded the highest-quality material within the most efficient timeframe. Other fruit textile recipes called for chemicals such as calcium chloride to dry the material, however we decided to eliminate such ingredients.

Testing our Technical Challenges

We landed on four of the most promising looking samples, labeling them A through D, and evaluated their properties using a low-end tensile tester (LETT).

Analysing the Tests

We first converted the force-displacement graphs to stress-strain graphs. From here we could find the tensile strength, yield strength, and Young’s modulus. To generalize these findings, the results were averaged across all strips and the standard deviation was calculated. Outliers, identified by abnormal curve shapes or values that deviated significantly were discarded. These abnormalities were likely caused by sample slippage. Toughness, ductility, and breaking strength were not calculated, as the material didn’t fail during testing; the machine was halted once the banana fibers became visible.

Material Comparison

When plotted on the Ashby chart, the samples primarily fall within the elastomer category. This is expected, as the material is able to stretch and recover its original shape. Compared to leather, which was used as a reference material, the density is similar, while the stiffness is approximately ten times lower. This indicates that although the material replicates some properties of leather, its lower stiffness limits its suitability for applications requiring greater rigidity. Increasing the number of banana fibre layers may help improve stiffness in such cases.

Yeild

Tensile

E

A1

0,513043

0,64087

30

A2

1,07619

1,248095

47,2

A3

0,539091

0,808182

30,8

A4

0,384922

0,484701

20,3

A5

0,282372

0,347115

37,4

STDEV.

0,306929

0,348684

9,958314

Avg.

0,559123

0,705793

33,1

Mpa

Mpa

Mpa

Testing our Experiential Challenges

Through user testing, we evaluated our experiential goals of smell and feel. Participants were immediately curious to smell the material and noted that the scent was different from what they expected. Some detected hints of orange, while others found it difficult to identify. Overall, participants agreed that the scent was very subtle and largely neutral. Users described the material as smooth to the touch. Although it did not resemble any textile they were familiar with, they found it comfortable against the skin. We also received feedback on the material’s color. Participants did not enjoy the orangey tone in combination with the fibers and small peel grains. While color was not one of our experiential goals, this feedback is an interesting insight to explore in future iterations. In conclusion, we successfully met our experiential challenges. Participants responded positively to the neutral scent and smooth feel of the material.

Findings

Our technical challenge required the material to be both strong and flexible. Sample A had the highest average yield strength, suggesting it was the strongest. Sample C, with the lowest Young’s modulus, was the most flexible, but was not selected due to inconsistency in performance. Samples A and D had similar stiffness, but D’s much lower yield strength ruled it out as a viable option. Therefore we identified the most promise in Sample A, see results on the left.

Material & Application Decision

Based on the technical and experiential tests, we decided to proceed with Sample A for our material recipe. We selected a handbag as the test application, designed to be strong enough to carry 2 kg of contents. A 3D model was created to perform a Finite Element Analysis (FEA) using material properties obtained from the LETT tests. The bag was fixed at the top of the strap, a 20 N load was applied to the bottom interior of the bag to simulate stored items, and Gravity (9.81 m/s²) was also applied to the simulation. The FEA allowed us to identify deformation zones, which were mainly seen in the strap. In addition to the FEA, we deconstructed an aged handbag to observe areas of natural wear and tear. We observed unexpected aging in the base of the bag.

The FEM analysis, combined with the bag autopsy, informed our design improvements. In the weaker areas of the bag, we opted for a thicker quasi-lateral fibre placement, while in the rest of the bag we used a thinner bilateral fibre placement.

Material Manufacturing

The final recipe proportions will remain undisclosed but the main three ingredients include orange peels, banana fibers, and sodium alginate. Orange Peel is at the core of the material's base. The peel contains cellulose, which contributes to the biodegradability of the material as well as its water retention, stopping the material from going brittle (Fatema et al., 2022). The Banana Fiber provides strength, structure and reinforcement. The Sodium Alginate, derived from seaweed is used due to its thickening, gelling agent, moisture retaining and emulsifying properties (Vasliauskas, 2020). This is what is believed to give our material elasticity, as well as its leathery texture.

Final Handbag (Test Application)

Future Applications

Now that our material is finalized and tested, my groupmate Isabel and I are transforming this project into a product line of three new applications. This is just the beginning, new products coming soon...